THE CHALLENGES OF RAPID PRODUCT DEVELOPMENT

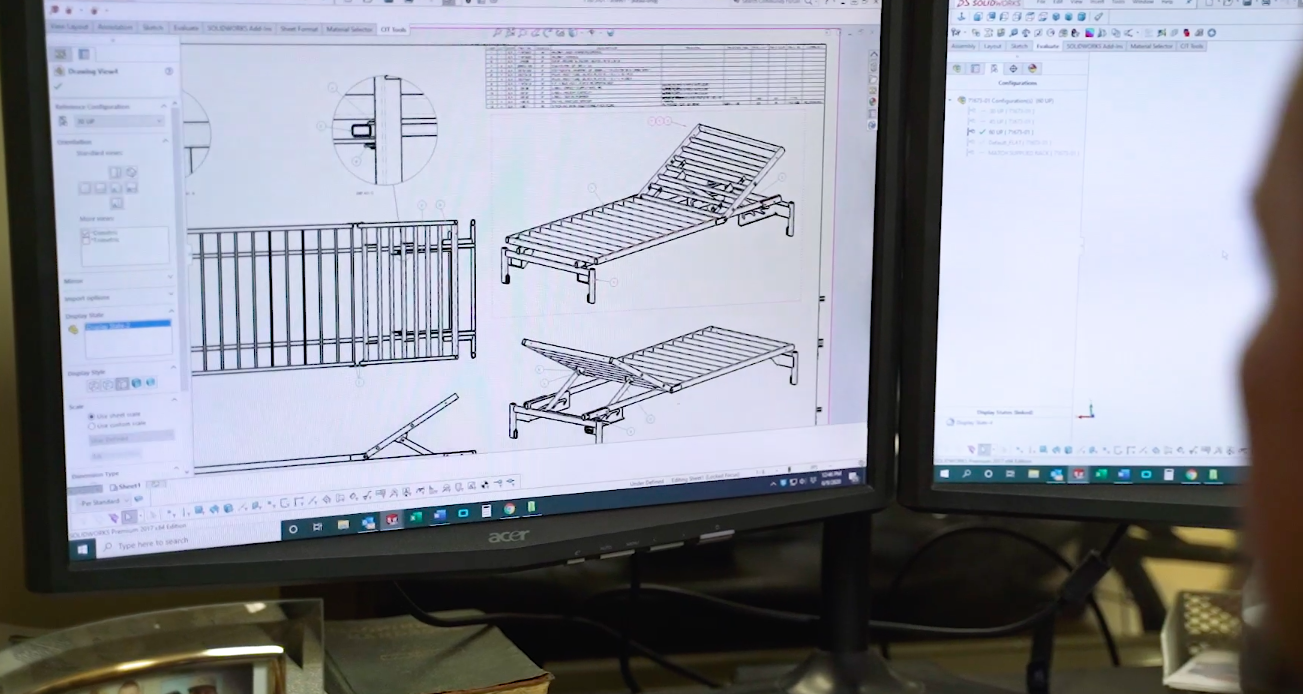

When the COVID health crisis caused a shortage of hospital beds, CIT had to manufacture and produce new portable, versatile beds – and they had to do it fast.

A 12-week process became a 2-week process. To go from concept to manufacturing to the market can be expected to take two to three months to complete. With a dedicated team and an important deadline, CIT had a product ready to test one week after receiving the assignment and had their first shipment ready in two weeks.

This rapid product development was far from easy, though.

The customer sent a picture of the product they had in mind, but this design didn’t fit CIT’s manufacturing strengths. They wouldn’t be able to make the deadline. So, the design team started from scratch to change the product idea into a plan that would for CIT and was feasible to complete in two weeks. This challenge alone couldn’t have been overcome without a dedicated team.

The process and timetable were much different than what any CIT employee was accustomed to.

“Design team, who worked the weekend, had to finish the design in 5 days, purchasing had to work on getting material lined up and manufacturing engineering had to have the fixtures in a matter of days,” Kim Wuertemberger, CIT founder, said.

Everyone felt the pressure.

“Everyone did was necessary,” Wuertemberger said. “Our welding robot programmer worked all night to have the first bed complete ready for testing one week after design was given the project. Our weld crew worked the weekend to have a minimum of fifty beds by Monday morning.”

This wasn’t just another project. The rapid-response bed meant that employees had to work more and harder than they ever had before. Regular work hours were nonexistent. There wasn’t time for mistakes. Despite the challenges, CIT Inc. did it, and they did it with grace.

“Our experience in the type of manufacturing that we do can have its share of pitfalls,” Wuertemberger said. “We have enough experience to be able to identify where are challenges are and tackle the long lead issues first to keep projects on track. Consequently, what we did on this project is we can do for others when required!”

To have the beds ready for shipment in just two weeks was – to put it simply – remarkable. The CIT team knew the importance of this product and they stepped up to overcome. For CIT, there is no challenge too big. Not even rapid product development.