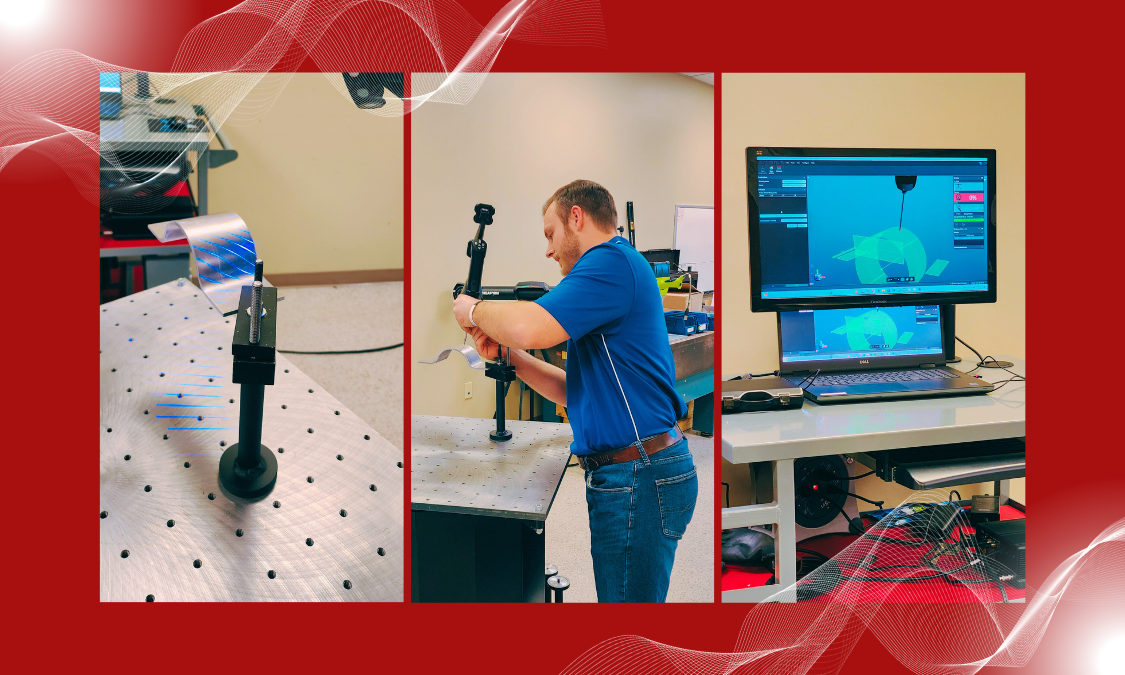

QUALITY TEAM ADDS 3D SCANNING CAPABILITY

As our Quality team crafts our path forward to provide the latest technology to our clients. We’ve added 3D scanning capabilities to provide real-time, accurate feedback to the production floor. This cannot be done using traditional equipment - as well as save significant time. Check out this interview with Reed Bolser, quality technician.

What is your role with the 3D Scanning / CMM effort at CIT?

Reed: I run, operate, and communicate the results of the 3d scan on our products to management and production.

Why is it important?

Reed: It allows us to provide real-time, accurate feedback to the production floor to achieve quality products.

What makes it unique?

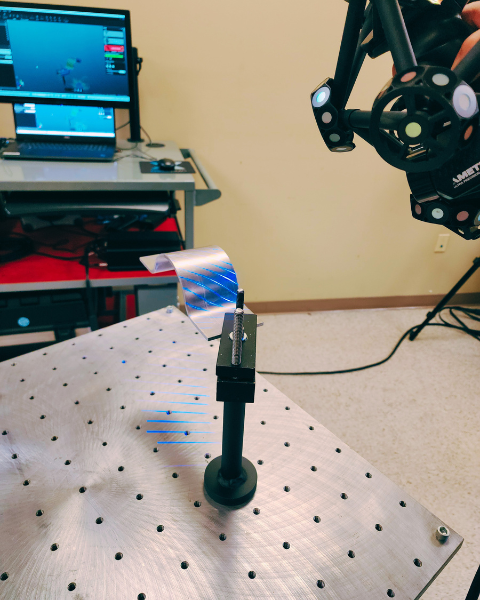

Reed: Well, CIT provides a 3d scan of the physical product, allowing us to achieve measurements that cannot be captured using traditional measuring equipment. We can do anything from reverse engineer, inspect non geometric shapes, and look at a part we scanned years ago if we wanted to.

How do you adapt to the ever-evolving product lines at CIT?

Reed: We have designed and built many items that allow us to use this equipment and technology in different areas. We have a small fixturing table that we designed to allow us to inspect specific parts. We have designed and built a mobile workstation so we can be more versatile.

How do you stay up to date with the equipment and technology in this field?

Reed: At CIT, continuous education is part of our approach. We watch online webinars, go to seminars, reach out to people, and create contacts that we can reach out to for insight. Like a professor from the University of Connecticut.

Any thoughts, ideas, or wins you want to share about the 3D Scanner / CMM work?

Reed: A major win is being able to adjust the flatness of a robot laser track, that is 28ft long. By using this equipment, we were able to get it flat within 0.015” within minutes.

What do you love about your work?

Reed: To me, it feels like I am working with equipment from the future. The vast array of scenarios that this technology provides is truly incredible.

Thank you, Reed, and we wish you the best!